Introduction

The logistics and supply chain industry is the backbone of the global economy. From ensuring that raw materials reach factories on time to delivering products to customers across continents, efficient supply chain management determines the success of businesses worldwide. But with increasing complexity, rising customer expectations, and global disruptions (such as pandemics, geopolitical conflicts, and climate events), traditional supply chain models are struggling to keep up.

This is where artificial intelligence (AI) steps in. Modern logistics and supply chain software now integrates smart AI features that improve forecasting, optimize operations, reduce costs, and enable more resilient networks. For developers and businesses, understanding which AI capabilities matter most—and how to implement them effectively—can make the difference between surviving and thriving.

In this guide, we’ll dive deep into AI-powered innovations in logistics and supply chain software. You’ll learn which features deliver the highest ROI, how they work under the hood, and real-world examples of companies deploying them successfully.

Why AI Matters in Logistics and Supply Chains

Supply chains are inherently data-rich but insight-poor. They involve:

- Structured data: inventory levels, shipment records, transaction logs.

- Unstructured data: emails, weather reports, social media posts, IoT sensor data.

AI thrives in this environment because it can process massive, messy, and multidimensional datasets faster than humans or rule-based systems.

The benefits of AI in supply chain software include:

- Efficiency Gains: Automating routine tasks like scheduling, routing, and tracking.

- Predictive Accuracy: Reducing stockouts, overstock, and demand miscalculations.

- Risk Resilience: Anticipating disruptions from external factors like port closures or weather events.

- Sustainability: Optimizing transport routes and reducing waste, lowering carbon footprints.

Example: DHL reported that AI-driven route optimization reduced delivery times by 15% while cutting fuel costs significantly.

Core AI Features Transforming Logistics & Supply Chain Software

Let’s break down the smart AI capabilities that are reshaping supply chain management today.

1. AI-Powered Demand Forecasting

Demand forecasting is the holy grail of supply chain planning. Traditional methods rely on historical sales, but AI goes further by incorporating:

- Real-time market signals (e.g., search trends, promotions).

- External factors (e.g., weather, holidays, economic indicators).

- Nonlinear demand patterns recognized via machine learning.

How it Works:

- Models such as LSTMs (Long Short-Term Memory networks) or transformers analyze time-series data.

- AI adjusts forecasts dynamically as new data arrives.

Impact:

- Retailers reduce excess inventory while avoiding out-of-stock events.

- Manufacturers align production schedules more accurately with customer demand.

Case Example: Walmart uses AI forecasting models across thousands of stores, reducing stockouts by 30%.

2. Intelligent Route Optimization

AI transforms logistics routing by analyzing variables in real-time:

- Traffic patterns.

- Fuel costs.

- Driver schedules.

- Vehicle capacity.

Smart Features Include:

- Dynamic rerouting during transit.

- Multi-stop route optimization.

- Emissions-aware route selection.

Analogy: Think of it like Google Maps, but scaled for entire fleets with millions of deliveries daily.

Developer Tip: Use reinforcement learning algorithms that learn from past delivery outcomes to continually improve.

3. Predictive Maintenance with IoT + AI

Fleet downtime is costly. AI + IoT sensors help predict failures before they happen.

- Data Sources: Engine temperature, vibration levels, fuel consumption.

- Models: Anomaly detection and regression models flag unusual patterns.

- Outcome: Schedule maintenance proactively, preventing breakdowns.

Example: UPS saves millions annually using AI-driven predictive maintenance, extending the lifespan of delivery trucks.

4. Smart Warehouse Automation

Modern warehouses are AI-powered ecosystems:

- Robotic Process Automation (RPA) for repetitive tasks like picking and packing.

- Computer Vision for inventory counting and quality checks.

- AI-Driven Layout Optimization to minimize worker travel time.

Scenario: An AI system might rearrange shelves overnight based on predicted demand for the next day’s orders.

5. AI for Real-Time Supply Chain Visibility

End-to-end visibility has long been a supply chain dream. AI delivers it by:

- Integrating disparate data sources (suppliers, carriers, ERP systems).

- Providing predictive ETAs (Estimated Time of Arrival) for shipments.

- Detecting bottlenecks in real-time.

Case Example: Maersk’s TradeLens platform uses AI and blockchain to give customers visibility into every stage of their shipments.

6. Risk Management & Disruption Prediction

Global supply chains face constant risk: political instability, pandemics, strikes, natural disasters. AI models predict and mitigate these risks by:

- Scanning global news and regulatory updates.

- Using graph neural networks to simulate supply chain interdependencies.

- Suggesting alternate suppliers or routes automatically.

Example: During COVID-19, companies with AI-powered risk management systems adjusted sourcing faster than competitors, ensuring business continuity.

7. Personalized Customer Experiences

Beyond efficiency, AI enhances customer-facing features:

- Real-time shipment tracking.

- Predictive delivery windows.

- Proactive notifications about delays.

Developer Insight: Build APIs that integrate tracking AI with customer portals, creating Amazon-like transparency for B2B and B2C customers.

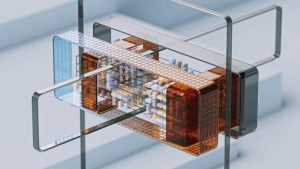

Developer’s Technical Blueprint for AI in Supply Chains

Building AI-driven logistics software requires an integrated architecture:

- Data Layer: IoT devices, ERP systems, CRM, external APIs (e.g., weather, fuel prices).

- Processing Layer: ETL pipelines, data warehouses, and preprocessing engines.

- AI/ML Models: Demand forecasting, routing, anomaly detection, NLP for unstructured data.

- Application Layer: Dashboards, mobile apps, fleet management tools.

- Security Layer: Data encryption, compliance (GDPR, SOC 2).

Workflow Example:

- IoT sensor streams → cloud storage → anomaly detection model → predictive maintenance dashboard → automated work order for mechanics.

Key Challenges in Implementing AI Features

Even though AI is transformative, developers face hurdles:

- Data Quality Issues: Supply chains often deal with messy, inconsistent data.

- Solution: Invest in preprocessing and data governance frameworks.

- Scalability: Models that work on small datasets may fail on enterprise-level logistics data.

- Solution: Use distributed systems and cloud-native architectures.

- Integration with Legacy Systems: Many logistics firms still rely on outdated ERP systems.

- Solution: Build middleware APIs and modular microservices.

- Trust & Adoption: Stakeholders may distrust AI decisions.

- Solution: Provide explainability features (confidence scores, traceability).

Case Studies: AI in Action

Case Study 1: Amazon’s Robotics + AI Warehousing

Amazon uses computer vision + AI-driven robotics to reduce picking times by 25%, handling millions of SKUs seamlessly.

Case Study 2: FedEx’s SenseAware Platform

FedEx developed an IoT + AI solution that tracks sensitive shipments (like pharmaceuticals) in real-time, ensuring compliance with strict temperature regulations.

Case Study 3: DHL & AI-Driven Routing

By combining AI with traffic and weather data, DHL optimized routes for its European fleet, cutting CO₂ emissions significantly.

Best Practices for Developers

- Adopt Modular AI Models: Build forecasting, routing, and risk prediction as independent modules.

- Prioritize Explainability: Users must trust AI-driven recommendations.

- Leverage Cloud + Edge AI: Edge AI supports real-time logistics decisions on the ground.

- Test with Real Users: Validate features with logistics managers, drivers, and warehouse staff.

- Focus on ROI: Every AI feature should tie directly to measurable outcomes (cost savings, reduced delays, sustainability).

1. Generative AI for Supply Chain Documentation

Generative AI isn’t just for chatbots—it’s transforming logistics paperwork and compliance.

- Applications:

- Auto-generating bills of lading and customs documentation.

- Drafting compliance reports for global trade.

- Creating structured insights from unstructured text (emails, invoices).

- Developer Tip: Fine-tune models on logistics-specific corpora to avoid inaccuracies. Hallucinations in compliance documents could mean regulatory penalties.

Example: A freight forwarding company can automatically generate multilingual customs declarations, cutting clearance times by 40%.

2. Digital Twins in Logistics

A digital twin is a real-time virtual model of a supply chain. AI enhances these simulations by:

- Predicting demand spikes.

- Stress-testing disruptions (e.g., port closures, strikes).

- Optimizing warehouse layouts or fleet configurations.

Scenario: A manufacturer simulates how a typhoon in Southeast Asia would affect suppliers, then preemptively reallocates shipments.

3. Multi-Agent AI Systems

Instead of one central model, multi-agent AI systems simulate negotiation and coordination among supply chain stakeholders.

- Use Cases:

- Suppliers, carriers, and distributors negotiating delivery schedules.

- AI agents representing different logistics partners to balance costs and service levels.

Analogy: It’s like each stakeholder has a smart “AI negotiator” sitting at the table, aligning decisions faster than humans could.

4. AI-Enhanced Sustainability Tracking

Sustainability is no longer optional—it’s a competitive advantage. AI helps by:

- Tracking carbon emissions per shipment.

- Suggesting greener transportation alternatives.

- Optimizing packaging to reduce waste.

Case Example: IKEA uses AI to minimize empty space in packaging, reducing shipping emissions significantly.

5. Edge AI in Real-Time Logistics

While cloud-based AI powers analytics, edge AI brings intelligence closer to the action.

- Applications:

- Delivery drones adjusting routes mid-flight.

- IoT-enabled forklifts in warehouses making safety decisions instantly.

- Cold-chain monitoring devices ensuring pharmaceuticals stay within temperature ranges.

Developer Note: Optimize for low latency and lightweight models since edge devices have limited resources.

Real-World Case Studies of Advanced AI in Logistics

Case Study 1: Maersk’s Digital Twin Supply Chain

Maersk uses digital twins + AI simulations to optimize container movements globally. During the Suez Canal blockage, these simulations helped reroute cargo faster than competitors.

Case Study 2: JD.com and Warehouse Robotics

JD.com, a Chinese e-commerce giant, built fully automated warehouses where AI-driven robots handle 90% of tasks, monitored by computer vision and predictive models.

Case Study 3: UPS Orion + AI Optimization

UPS’s ORION (On-Road Integrated Optimization and Navigation) system uses AI route optimization, saving the company 10 million gallons of fuel annually.

Monetization Models for AI-Powered Logistics Software

Building smart AI features is only half the battle—developers and startups must also design sustainable business models. Here are proven approaches:

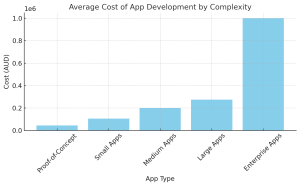

1. SaaS Subscriptions

- Tiered plans for small logistics providers vs. enterprise-scale operations.

- Example: $500/month for predictive analytics dashboards, $5,000/month for full-suite AI optimization.

2. Pay-Per-Use

- Useful for seasonal shippers.

- Example: $0.05 per optimized route, $1 per demand forecast batch.

3. API Licensing

- Offer AI capabilities (e.g., ETA prediction, demand forecasts) as APIs for integration.

- Example: $0.01 per API call for shipment-tracking predictions.

4. Enterprise Licensing + On-Prem Deployments

- Large corporates (airlines, retailers) may demand private cloud or on-premises AI deployments for compliance.

5. Hybrid Models

- Base SaaS fee + variable API usage costs.

Tip for Developers: Start with SaaS for SMBs, but build API-first architecture for scalability into enterprise markets.

Future Trends in AI for Supply Chain & Logistics

1. Autonomous Logistics

- Self-driving trucks and delivery drones guided by AI.

- AI-powered control towers orchestrating end-to-end autonomous operations.

Timeline: Widespread adoption expected within 5–10 years, pending regulation.

2. AI + Blockchain for Transparency

- Immutable blockchain records ensure trustworthy supply chain data.

- AI layers analyze this data for fraud detection and compliance monitoring.

3. Human-AI Collaboration

- Logistics managers will increasingly act as AI supervisors—overseeing models rather than handling manual tasks.

4. Hyper-Personalized Delivery

- AI will enable delivery time slots tailored to each customer’s habits.

- Predictive models may even anticipate orders before customers place them.

5. AI-First Sustainability Regulations

- Governments may mandate AI-driven emissions tracking.

- Companies failing to adopt AI sustainability tools could face penalties.

Framework for Developers: Building Resilient AI Supply Chain Systems

Here’s a five-phase framework developers can follow:

- Foundation

- Clean, structured data pipelines.

- Integration with ERP, WMS, and TMS.

- Core AI Features

- Demand forecasting, route optimization, predictive maintenance.

- Advanced AI Features

- Digital twins, multi-agent systems, edge AI.

- Compliance & Security

- GDPR, SOC 2, ISO compliance baked in.

- Role-based access control.

- Continuous Learning

- Feedback loops from real-world outcomes.

- Retraining models quarterly with updated data.

Conclusion

AI is no longer just an add-on feature in logistics software—it is the engine driving the future of supply chain efficiency, resilience, and sustainability.

From intelligent demand forecasting to autonomous fleets and digital twins, AI enables organizations to do more with less—cutting costs, anticipating disruptions, and meeting rising customer expectations. For developers, the opportunity lies in designing AI systems that are explainable, secure, and scalable—features that not only optimize today’s operations but also future-proof supply chains for tomorrow.

The companies that win in this space won’t just adopt AI; they’ll make it a core strategic asset, embedding intelligence across every layer of the supply chain.

FAQs on AI in Logistics and Supply Chain

1. What is the biggest impact of AI in supply chains today?

The most immediate impact is demand forecasting and route optimization, reducing costs while improving delivery accuracy.

2. Can AI prevent disruptions like port closures or pandemics?

AI cannot prevent them, but it can predict risks early and suggest mitigation strategies such as alternate suppliers or routes.

3. What skills should developers focus on to build AI for logistics?

Python, ML frameworks (TensorFlow, PyTorch), cloud platforms (AWS, Azure), and APIs for ERP/WMS integration.

4. How does AI improve sustainability in logistics?

By optimizing routes, reducing fuel usage, minimizing packaging waste, and tracking emissions in real time.

5. Is AI in logistics affordable for SMBs?

Yes. Many SaaS solutions offer tiered pricing, making AI accessible for small freight operators and e-commerce sellers.

6. What is the future of AI in logistics?

Expect autonomous logistics, AI + blockchain transparency, and hyper-personalized delivery to dominate the next decade.